ʻO nā kiʻi kiʻi kiʻi kiʻi

I. What isFurniture Board Flat Films?

As the name suggests,Furniture Board Flat Films refers to a processing technology that adheres decorative films (made of materials such as PVC, PP, and PET) smoothly to the surface of base materials (such as MDF, particleboard, and plywood) through cold pressing or hot pressing.

Furniture Board Flat Films’s core feature lies in "flatness" — meaning the film is completely attached to the surface of the base material, without involving any three-dimensional shaping or wrapping. The final product is what we commonly call "flat-laminated board" or "flat panel".

‘

‘

Ⅱ.Main Types and Characteristics ofFurniture Board Flat Films?

There is a wide variety of films used for flat lamination, which determine the final performance and appearance of the finished boards:

|

Type |

Characteristics |

Application Scenarios |

|

PVC Furniture Board Flat Films

|

The most common type with the highest cost-effectiveness. It comes in a wide range of patterns, offers good wear and stain resistance, and has stable physical properties. It also has a broad thickness range (0.1mm-0.8mm is common). |

Cabinets, wardrobes, office furniture, interior partitions, laboratory countertops. |

|

PP Furniture Board Flat Films

|

The top choice for environmental friendliness. It is usually odorless, chlorine-free, and recyclable. It has a soft touch but is slightly inferior to PVC in terms of wear resistance and high-temperature resistance. |

Children’s furniture, food packaging-grade furniture, and home spaces with extremely high environmental requirements. |

|

PET Furniture Board Flat Films

|

A representative of high performance. It has an extremely smooth and delicate touch, excellent wear resistance, high-temperature resistance, and scratch resistance. It is environmentally friendly and recyclable. |

High-end cabinets, wardrobes, commercial furniture, and electrical appliance panels. |

|

Acrylic (PMMA) Film |

Features high gloss and high hardness. It has a high surface hardness, with a glossiness of over 95°, delivering an excellent mirror effect and being resistant to scratches. However, its price is relatively high. |

High-gloss cabinet doors, modern-style furniture, and display cabinets. |

|

Metal/Leather/Cloth Texture Film |

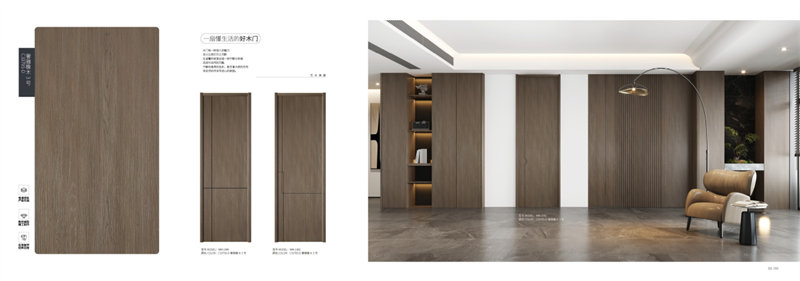

For special effects. In addition to wood grain,the flat lamination process is also applicable to films that simulate various special effects such as cement texture,metal texture , and leather texture. |

Accent walls |

Ⅲ.Advantages of the Furniture Board Flat Films:

1.High Production Efficiency: Furniture Board Flat Films are highly suitable for standardized mass production, large-scale,featuring a high degree of prominent automation and cost-effectiveness.

2.Wide Base Material Compatibility: Furniture Board Flat Films can be applied to various flat base materials, such as cement boards, particleboard, metal plates and multi-layer boards, and even medium-density fiberboard (MDF).

3.Double-Sided Lamination Capability: Furniture Board Flat Films can be laminated on both sides.Different colored films are often used to distinguish the back and front sides. This balances the internal stress of the board effectively.

4.Diverse Visual Effects: Furniture Board Flat Films can perfectly present a variety of high-precision printed patterns, such as artistic patterns, solid colors,stone grain, and wood grain.

5.Excellent Performance:Furniture Board Flat Films provide good protection for the base material, endowing it with properties such as moisture resistance, wear resistance,easy cleaning, and water resistance.

Ⅳ.Comparison with the "Wrapping" Process

The best way to understand Furniture Board Flat Films is to compare it with the wrapping process:

|

Feature |

Furniture Board Flat Films |

Wrapping Films |

|

Shaping Capability |

Limited to flat surfaces only |

Enables 3D shaping; can wrap door panels with profiled edges |

|

Edge Sealing Treatment |

Requires separate edge banding strips, with seams |

Film wraps integrally, no seams, strong integrity |

|

Production Efficiency |

High; suitable for large-batch standardized production |

Lower; suitable for small-to-medium-batch production with diverse shapes |

|

Cost |

Low (inexpensive films + high efficiency) |

Higher (high requirements for films + low efficiency) |

|

Application Effect |

Flat door panels, cabinet bodies, countertops, partitions |

Profiled door panels, wall panels, door/window casing lines |

Furniture Board Flat Films are a cornerstone process in the panel furniture industry.As its unparalleled efficiency and cost-effectiveness, it provides us with the vast majority of flat-panel furniture that features reliable performance and stylish appearances.

When your demand is for furniture with large-batch production, standardization, and flat design, the flat lamination process is the optimal choice. If you pursue seamless, profiled, and highly integrated effects, you need to consider other processes such as wrapping or vacuum forming.

- View as